Every workplace relies on a number of electrical appliances to get through the day. Any disruption to the function of these devices could very well affect your workflow and consequently your bottom line. That is why Portable Appliance Testing (PAT) is such an integral part of your maintenance schedule. Regular PAT testing not only ensures the safety of your workplace devices but can also prevent larger problems from developing, saving you in long-term costs. Here are some things you can do to protect your business, premises, client, staff and their equipment.

Before you use an appliance, carry out a visual inspection to identify any serious problems. Have a look at:

If any of the above is damaged then report it to the responsible person and don’t use.

Where a device is positioned can do a lot to prevent damage in the long term. Locate your appliances in the workplace and check the following:

Things to avoid:

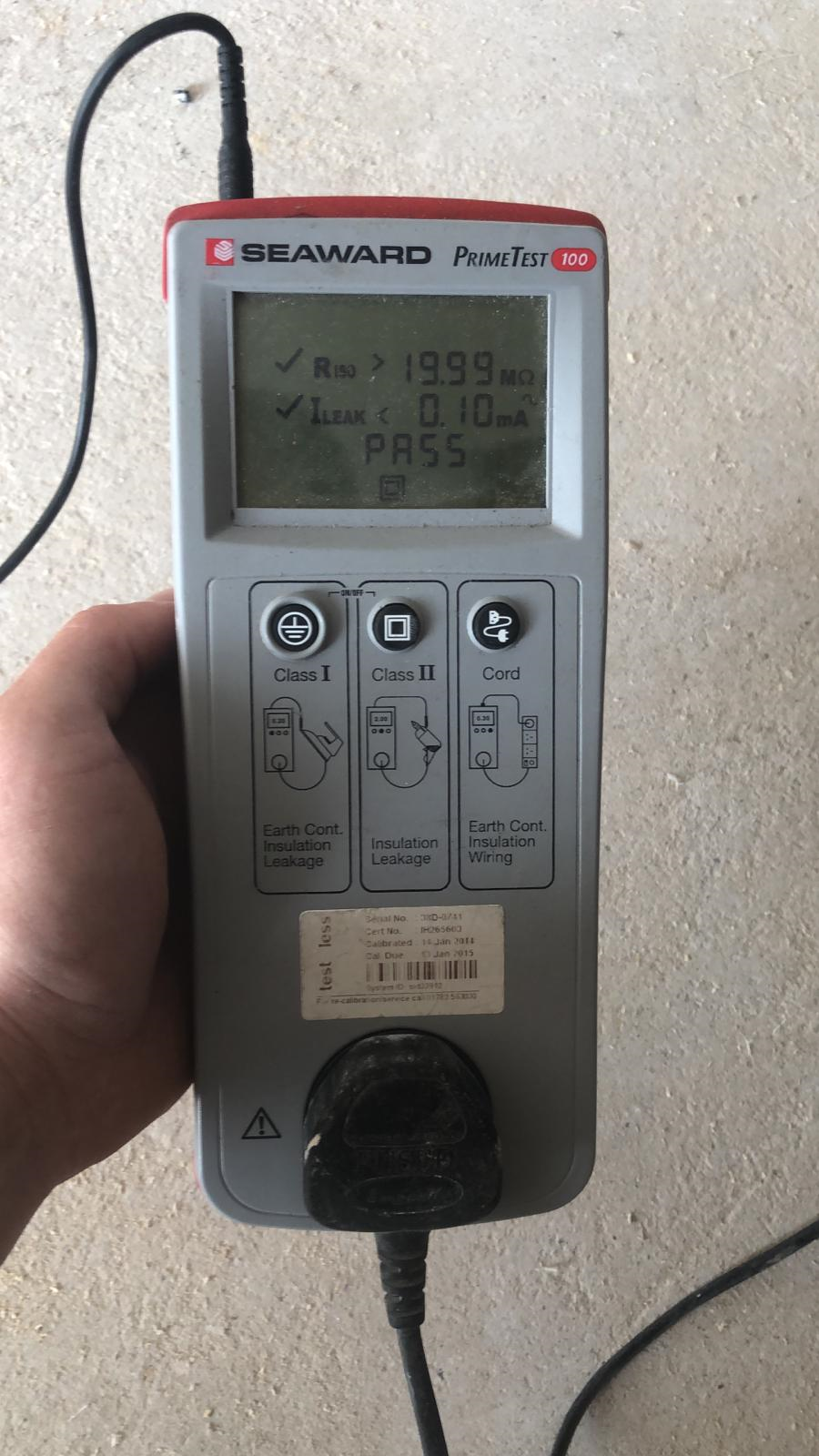

While you can help look for and prevent some damage to your portable appliances, it often takes a professional and experienced eye to determine if the device can be operated safely by staff and clients.

Here are some of the extra things we do while PAT testing:

While PAT is required by law under the Health and Safety at Work Act, it doesn’t need to be a chore. With your help and the experience of our professional staff, we can make the process efficient and hassle free. As more and more businesses look for ways to reduce costs, delaying or cutting down on your PAT testing could end up being a dangerous and expensive outcome.

Our team are available to discuss how you can improve the safety of our appliances. Please contact us at

info@karsonsconsulting.com for expert advice.

Karsons Consulting are members of the Chartered Institute of Building Services Engineers, The Association of Consultancy and Engineering, British Institute of Facilities Managers and the Building Services Research and Information Association.