Here at Karsons Consulting we advise clients on the compliance of a number of UK and EU regulations which have a huge impact on the operations of a business. In this blog, we highlight legislation for companies that need to meet the F-Gas Regulations.

What are F-Gases?

Fluorinated gases (F-gases) are a family of man-made gases used in a range of industrial applications. Because they don’t damage the atmospheric ozone layer, they are often used as substitutes for ozone-depleting substances. However, F-gases are powerful greenhouse gases, with a global warming potential (GWP) of up to 23,000 times greater than carbon dioxide (CO2). The way GWP is calculated was revised by the 2015 regulations, and so reflects the equivalent tonnes of CO2 based on the individual Hydrofluorocarbons (or blends).

What does this mean?

Any two AC units of comparable specification and size could have very different GWP depending on the individual HFC used. In turn, this means that checking the actual HFC used in each device is vital for regulatory compliance.

In other words, a device may not come under regulations with one particular HFC, whereas it could if charged with another. The larger the asset register then the greater the risk of confusion, especially where the devices were procured over a period of years or where site ownership has changed and records may be difficult to verify.

These regulations are particularly relevant for operations of stationary refrigeration, air conditioning and heat pumps systems. Such companies' operating equipment containing these gasses have a legal obligation to comply with the EC F Gas Regulation 843/2006 article 3 and Regulation EC 1516/2007.

What are the regulations?

In March 2014, the EU passed the F-Gas Regulation to reduce F-Gas emissions by 79% between 2015 and 2030, by cutting HFCs with a high Global Warming Potential (GWP).

The regulations enforce the following items:-

At Karsons Consulting, we provide a maintenance auditing facility to ensure that all buildings operating the use of F-Gases are compliant with these regulations. This also ties in with our accreditation as CIBSE Low Carbon Consultants where we have approved air conditioning inspectors in house.

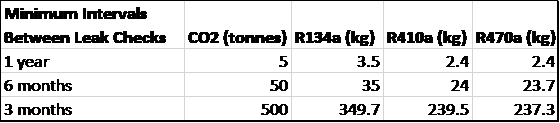

How Often Should They Be Leak Tested?

How many kilograms of F-gases are in your devices determines how often you should be testing them. Services with higher amounts need to be more frequently tested due to the greater danger of leakage.

The thresholds at which leak check intervals are specified are expressed in terms of CO2 equivalent.

They take into account both the quantity of F-gas in the equipment and the GWB of the F-gas.

This table below sets out the:

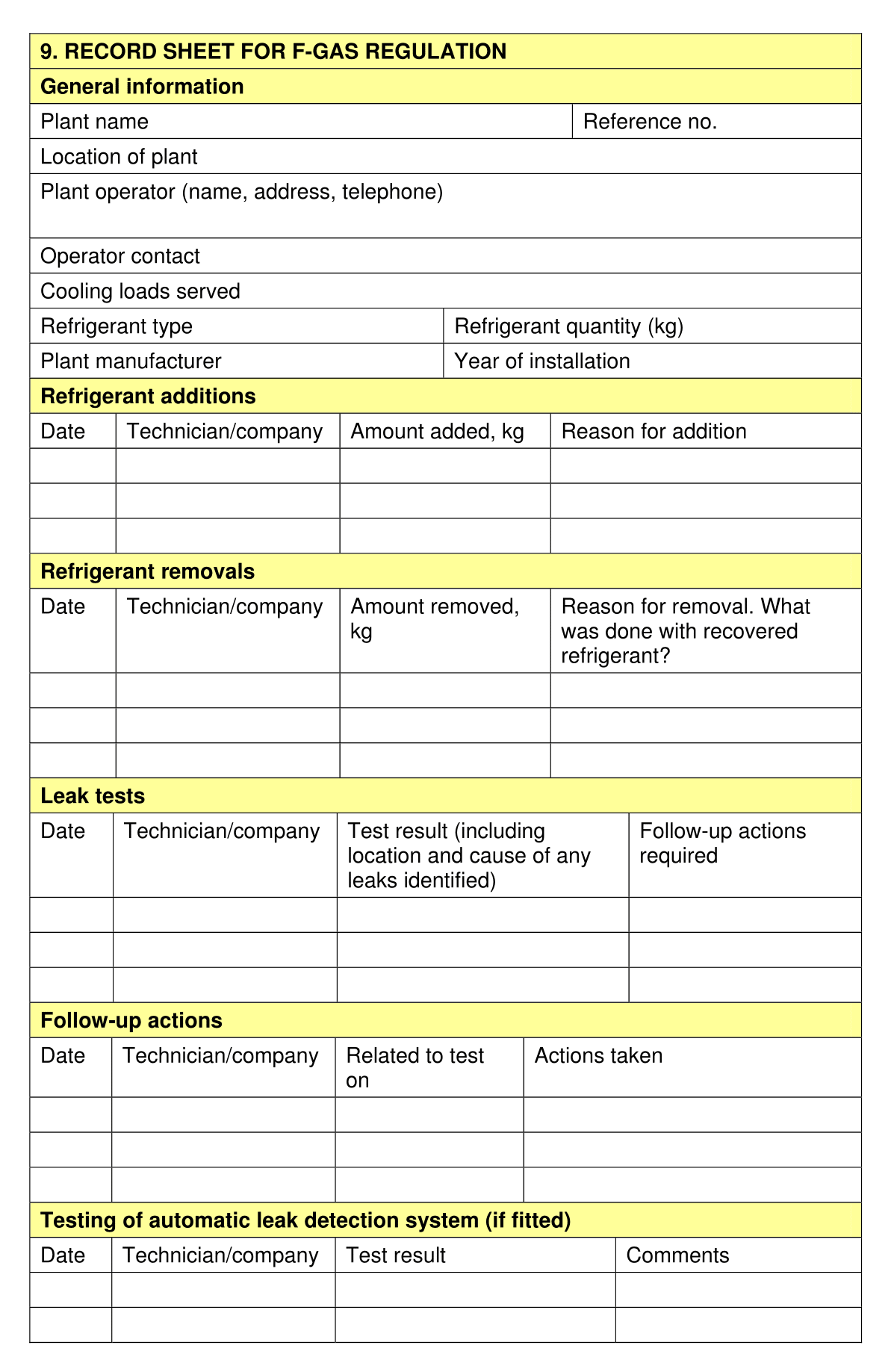

An Example Log Sheet

The below is an example of a log sheet to use when checking your F-gas devices

What is the Ideal Refrigerant?

In evaluating alternative refrigerants it is necessary to consider desirable attributes:

What is the Correct Refrigeration System for Your Building?

Companies are limited to the choice of system that they design/select for their choice of air conditioning system. This is based on cost and industry guidance. For example, the major manufacturers have plentiful stock of the components of refrigeration components as well as the HFC gasses and until stronger legislation is imposed, HFCs and HFC blends will still be used; but as previously mentioned, the lifecycle on these is finite.

HFCs and HFC blends

These refrigerants offer good properties and may provide suitable refrigerants across a range of application. The critical issue in deciding whether to employ these refrigerants or an alternative is whether their GWP will restrict their use in the short or the medium term.

Hydrocarbons

Hydrocarbons have excellent refrigerant properties and very low environmental impact. But the obvious flammability risk means that hydrocarbons are better suited to small systems such as domestic refrigeration or small air conditioning systems. Application of hydrocarbon systems must be in accordance with EN378, which restricts the refrigerant charge depending on the category of occupied space, the system location, the system type, and other criteria. Detailed guidance on design, construction installation and operation of hydrocarbon systems are covered in ACRIB Guidelines and EN378.

Ammonia

Ammonia is widely used as a refrigerant in the food refrigeration and cold storage industries, on a count of its excellent thermodynamic and thermos-physical properties. As with hydrocarbon refrigerants, the flammability risk (and the toxicity risk) limits the application of ammonia systems. Application of ammonia systems must be in accordance with EN378, which restricts the volume of refrigerant charge employed depending upon the category of occupied space, the system location and the system type.

Carbon Dioxide

From an environmental point and safety point of view carbon dioxide is an excellent refrigerant. It is non flammable, odourless, non-toxic (although can cause suffocation at very high concentrations), has zero ODP and very low GWP. Considerable development is taking place on CO2 for small refrigeration systems including car air conditioning systems and the use of CO2 as a secondary refrigerant in conjunction with a hydrocarbon or ammonia chiller.

Other alternatives

Other alternatives such as the use of absorption cooling systems or natural sources of cooling such as the ground may present alternative cooling strategies.

There are two main points in summary of this blog;

Karsons Consulting are able to offer even more advice on HFC gases and other systems that need to be regularly checked. Contact us on info@karsonsconsulting and one of our experts will discuss your concerns in this regard

Karsons Consulting are members of the Chartered Institute of Building Services Engineers, The Association of Consultancy and Engineering, British Institute of Facilities Managers and the Building Services Research and Information Association.