In commercial property management, the most damaging asset failures are often the ones you don’t hear about until it’s too late. They don’t arrive with flashing warning lights or urgent calls from the night guard. Instead, they develop silently in the background, chipping away at efficiency, safety, and compliance.

By the time the fault is obvious, you are likely to face downtime, tenant complaints, and high repair costs. What can you do to avoid this?

In this article, we outline four building systems that can stop working with little warning – and what you can do to prevent it.

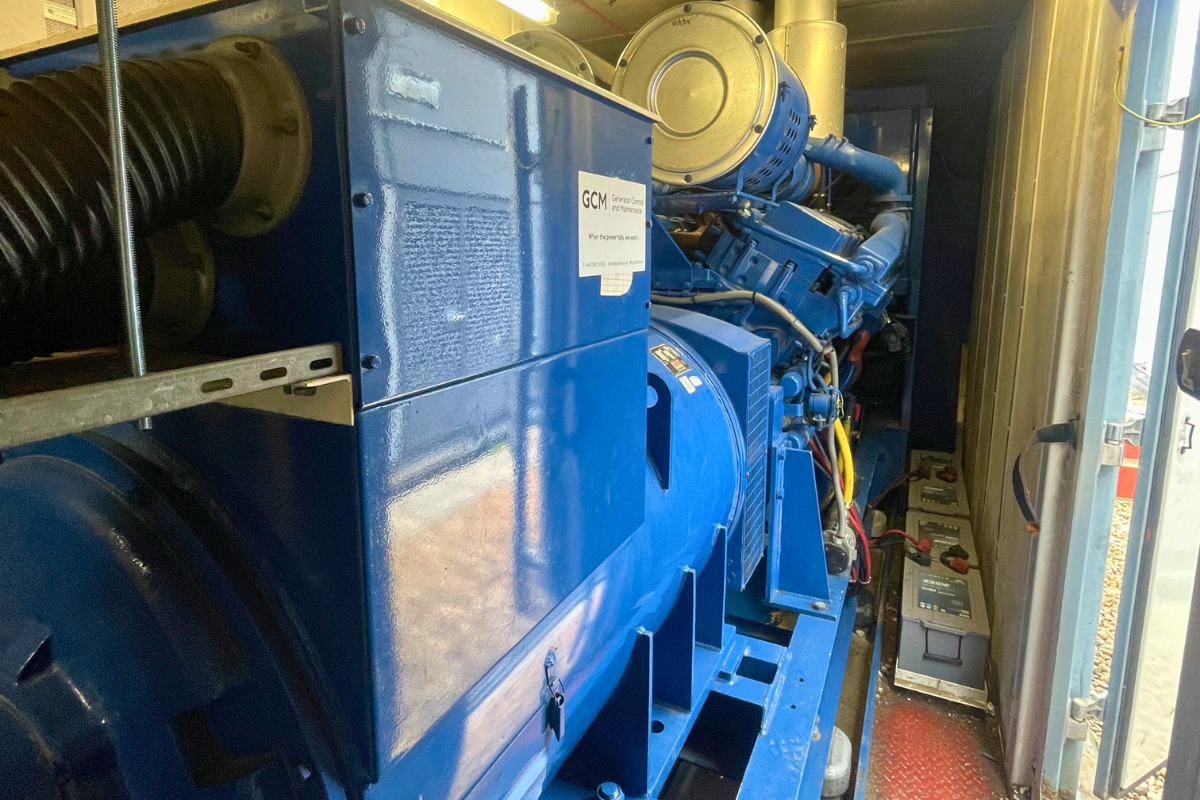

These systems exist for rare, critical events, which is why they’re often neglected between service visits. A generator that hasn’t been tested under realistic load conditions may start up fine during a weekly run, only to fail minutes into an actual power outage. Likewise, an ageing UPS battery might look “healthy” on a basic panel check, but have little actual capacity left.

Loss of lighting, security, IT systems, and critical plant during an outage can bring a building to a standstill, risking tenant dissatisfaction and reputational damage.

Preventative measures:

Carry out annual Black Building Tests to simulate a full loss of mains power.

Inspect fuel levels, coolant, batteries, and cabling for wear or corrosion.

Confirm critical systems are configured for automatic restart after restoration of power.

Sump pumps can seize, float switches can stick, and non-return valves can clog – all without triggering an alarm. You won’t know until you have standing water in a basement, plantroom, or lift pit. We’ve witnessed this before, where a failing drainage system quietly caused recurring basement flooding. Learn more about how we investigated this issue here.

Flood damage can cause expensive downtime, especially where electrical switchgear or lift systems are involved.

Preventative measures:

Test pumps under real water load, not just via “dry run” checks.

Inspect discharge lines for blockages and check non-return valves.

Schedule seasonal readiness checks before high-risk weather periods.

Chiller efficiency can degrade gradually due to fouled heat exchangers, low refrigerant charge, or scaling in cooling towers. In mild weather, the impact may be minimal – but come peak summer, you’ll likely face system alarms, low cooling output, and urgent calls from tenants.

Loss of cooling is particularly risky to commercial offices. It can result in reduced productivity, tenant complaints, and breaches of lease conditions.

Preventative measures:

Review BMS trend logs for declining performance.

Conduct seasonal commissioning checks before high-load periods.

Keep detailed refrigerant leak records to maintain both performance and F-Gas compliance.

Life safety systems are often “out of sight, out of mind” until a fire drill or real emergency. Fans may seize, dampers may stick, or controls may lose calibration – none of which will be obvious until the system is needed.

Failure here is more than an operational issue – it’s a life safety risk and a potential breach of legal compliance.

Preventative measures:

Conduct full functional testing as part of your statutory compliance plan.

Verify alarm integration, fan start-up, and damper operation.

Keep maintenance records to demonstrate compliance to the Fire Safety Order.

Modern commercial buildings operate as integrated ecosystems. Mechanical, electrical, and control systems often depend on each other – meaning a minor fault in one can silently compromise others.

For example:

A faulty pressure sensor in a closed-loop heating system causes a circulation pump to short-cycle, leading to premature pump failure.

An AHU control fault prevents frost protection pre-heating, allowing coils to freeze and split in winter.

A miscalibrated BMS temperature sensor causes simultaneous heating and cooling, overloading both systems.

If these interdependencies aren’t mapped and understood, failures can cascade. The visible fault might be just the final symptom – the real cause could be elsewhere in the chain.

Here are some ways you can prevent this:

Map asset dependencies during condition surveys and asset register updates.

When testing or maintaining one asset, check connected systems at the same time.

Use BMS trend logging to identify anomalies that indicate upstream or downstream issues.

Train facilities teams to understand not just individual systems, but how systems interact.

To avoid costly surprises:

Implement condition-based monitoring instead of purely time-based servicing.

Keep an accurate, live asset register so nothing falls through the cracks.

Integrate compliance checks (TM44 inspections, MEES upgrades, EPC reviews) into preventative maintenance schedules.

Invest in training for facilities teams to spot early warning signs and understand interdependencies.

Silent failures don’t respect budgets or timetables – they simply emerge. By recognising the assets most prone to undetected malfunction and applying robust testing, monitoring, and dependency mapping, commercial property owners and facilities managers can protect both operational uptime and compliance.

If you are worried about your asset’s operational performance, contact us! A Karsons maintenance audit can flag issues that might be hiding from you.

Karsons Consulting are members of the Chartered Institute of Building Services Engineers, The Association of Consultancy and Engineering, British Institute of Facilities Managers and the Building Services Research and Information Association.