.png)

CHP is an acronym for the word ‘Combined Heat and Power systems. CHP systems were originally introduced to the UK as an energy efficiency solution in the late 1990’s. CHPS units are growing in popularity as organisations and industries look to reduce their carbon footprint and reduce their energy bills. There are many variants of how the plant can be used, however they predominantly incorporate heat generation with electricity.

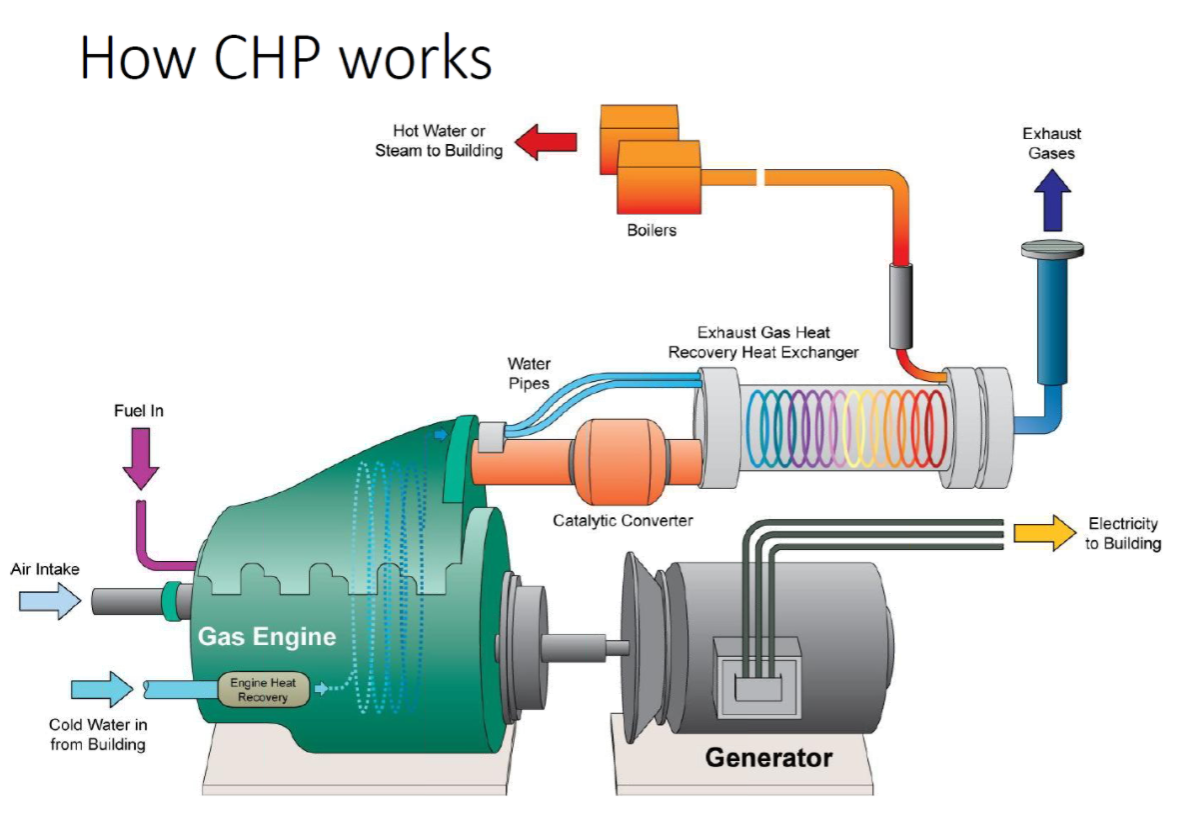

A CHP unit is essentially a heavy commercial diesel engine converted to run off a gas fuel supply. With all combustion engines, the primary outcome is that significant heat is generated through the heat of combustion and the friction of mechanical motion. In a car this would be reduced via oil, air- and water-cooling radiators. In a CHP system, this heat energy is captured via a heat exchanger and can be used to supplement heating, steam or hot water systems. Essentially the energy provided reduces the loading on plant item such as LTHW boilers, domestic hot water systems and steam systems. The secondary outcome of the engine is to drive a crank shaft which turns a generator to create electricity locally on the site, with the physics of electricity, the local electricity will be used before any electricity grid energy. CHP units can come in various sizes servicing large domestic buildings up to 2mw generation plants for buildings such as factories or warehouses.

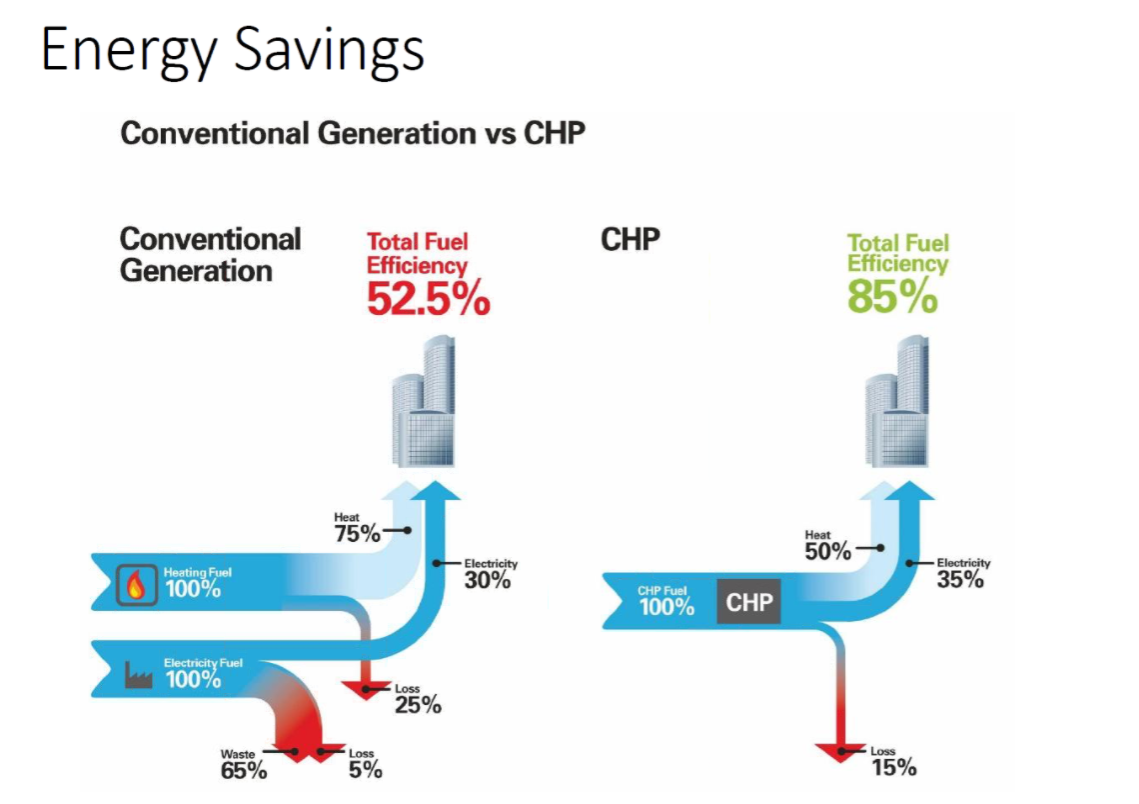

If designed correctly and maintained efficiently, CHP systems can reduce the combined cost of heating and electricity bills significantly meaning they can have a long-term return on investment (ROI) and can save significant carbon emissions to the atmosphere as the energy fuel efficiency produced can be up to 85%. If commercial businesses who have a CHP can prove they meet the design criteria (CHPQA), they will become eligible to offset their savings against the Climate Change Levy (CCL), introduced in 2001. This is known as CCL relief.

In Karsons experience, many CHP systems installed are incorrectly designed and specified. Some CHP systems do not meet the meet the energy saving criteria required for economic viability. In turn this means that the claimed ROI’s are not met. CHP equipment is advanced and in-depth feasibility studies should be undertaken to analyse the cost/energy benefits. CHP systems are still relatively new in concept, typically they are costly to install and are intrinsically design sensitive. Subsequently, there are many misconceptions about their operation and how to maintain them. This creates a ‘fear’ from the site managing agents, maintenance contractors and landlords who inherit them and are worried about how to approach the operation and maintenance of this equipment. If designed and maintained properly, CHPs should be cost effective.

It is also well documented that many sites also install CHP to prove their green credentials and pass planning consent. After this many sites leave their CHP equipment offline and resort back to conventional grid electricity and gas and electricity supplied heating and hot water services. This is not what the equipment was designed for and the wasted benefits are significant!

Karsons Consulting manage and consult on maintenance management on the maintenance management of CHP systems on prestigious sites such as Chelsea Barracks. Karsons also have a team of design engineers who have experience in the design and

maintenance process of this equipment. Karsons have produced detailed feasibility studies reviewing heat and power demands, operational requirements, running time requirements, gas pressures, acoustic environments and we can incorporate these into ESOS and BREEAM schemes.

Karsons can help from a maintenance, design or diagnostic perspective with your CHP system.

Karsons Consulting are members of the Chartered Institute of Building Services Engineers, The Association of Consultancy and Engineering, British Institute of Facilities Managers and the Building Services Research and Information Association.